Menu

Salvagnini 2

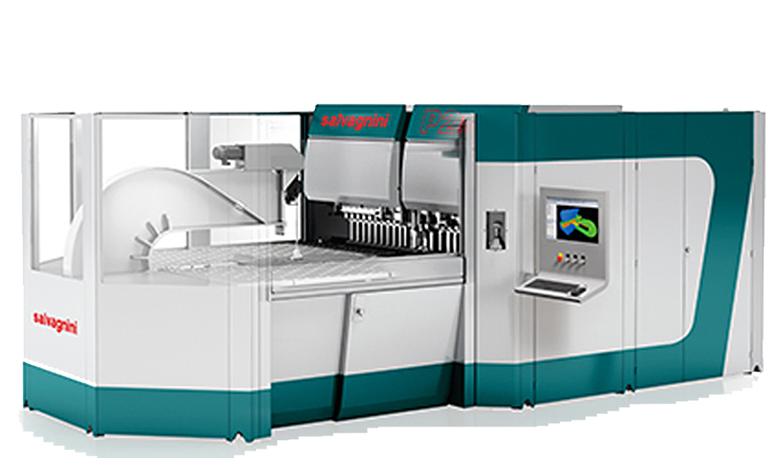

Panel Benders

Lean manufacturing the way you envision it. Salvagnini offers a large range of panel benders to fit our customers’ manufacturing styles and budgets.

There are 3 families available:

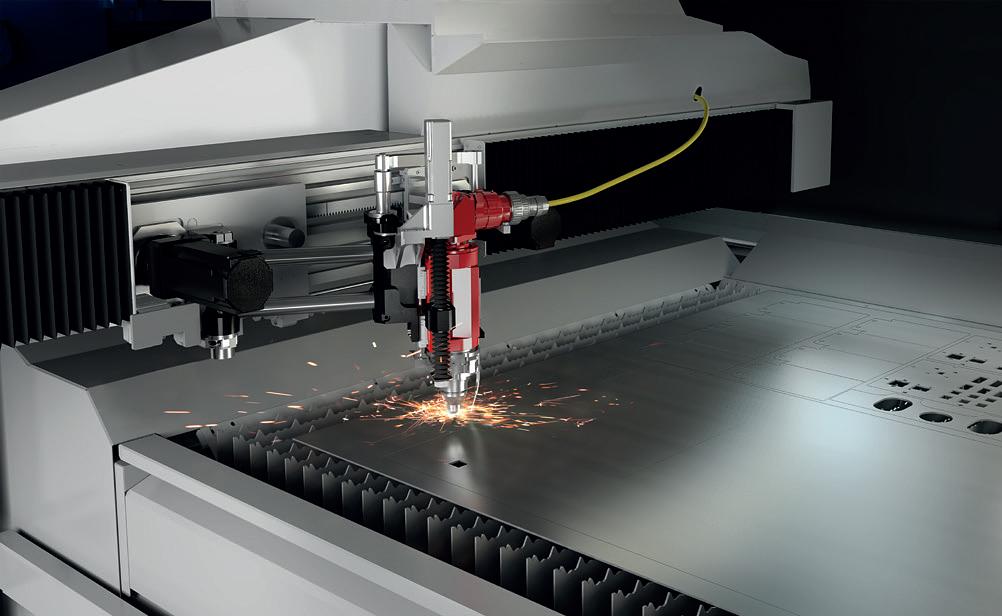

Fiber Lasers

Salvagnini Fiber Laser Blanking: A technology that makes organized, efficient cutting easy.

They offer productive and versatile solutions that offer reduced consumption and competitive operating costs.

Read More

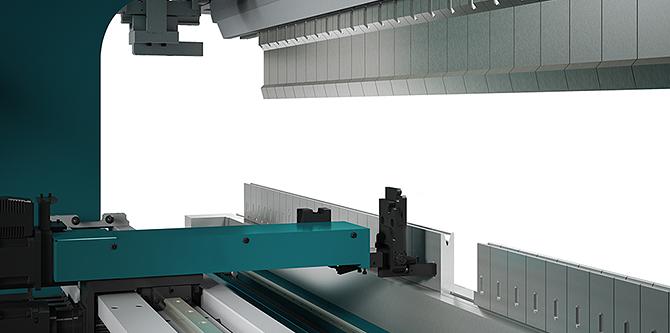

Press Brakes

Salvagnini offers flexible and productive solutions for your press brake needs. They are available in a wide range of sizes and automation options. MAC 2.0 technology guarantees bending repeatability and precision with each bend.

Read More

Punching Centers

Salvagnini Punching Centers offer an array of technology that guarantees high performance and process efficiency.

The S1 Hybrid Punching Machine satisfies the growing requirement for punch flexibility. The S4 Punching/Shearing Center is a flexible, productive automatic system.

Read More

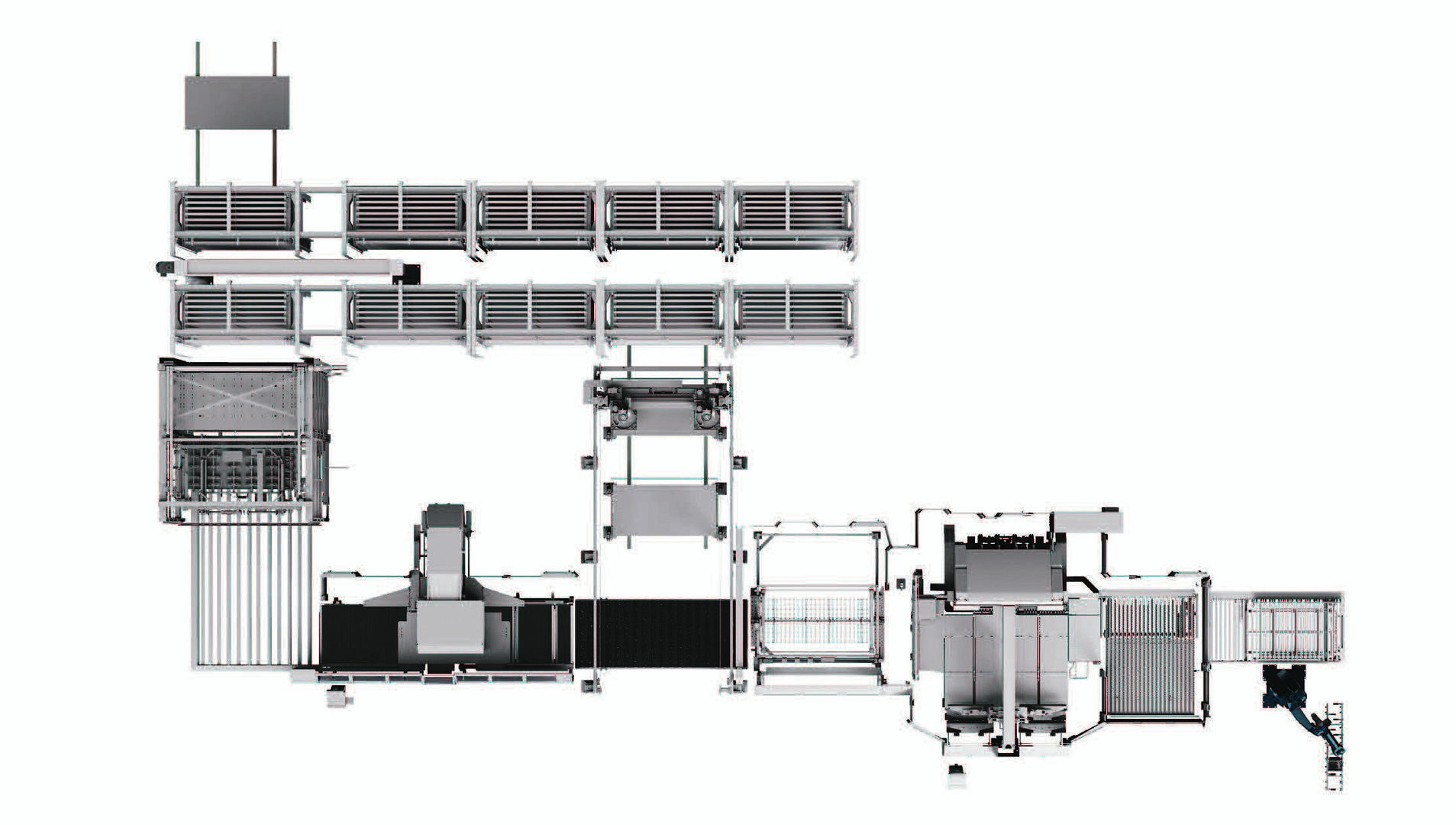

Factory Automation

Automatic job shops are not just for mass production. Salvagnini's ability to offer and produce flexible systems that are both automatic and integrated. These solutions are specifically designed to support the latest production techniques such as kit production, lean production, and unmanned production.

Read More

Panel Benders

P1

The P1 electric panel bender was developed to fit in 86 ft2 and use just 3kW of power. The P1 is ideal for companies working with cell production.

P2L

The most versatile and productive panel bender – it can produce a wide variety of metal parts, working automatically and according to different manufacturing strategies. Available in 4 models.

P4

The P4 Automatic panel bender is designed for easy integration with automatic handling devices. It is available in 9 models.

Fiber Lasers

L3

The L3 is a productive and versatile solution that offers reduced consumption and competitive operating costs.

L5

With the Salvagnini single-optic cutting head, the compass structure and the cutting parameters developed specifically for it, the L5 provides quality cutting across a wide range of thicknesses with high dynamics.

Press Brakes

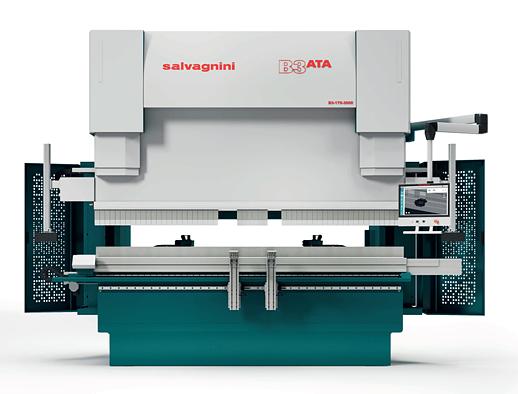

B3

The B3 combines the features and benefits of electric and hydraulic press brakes with options for automation and software.

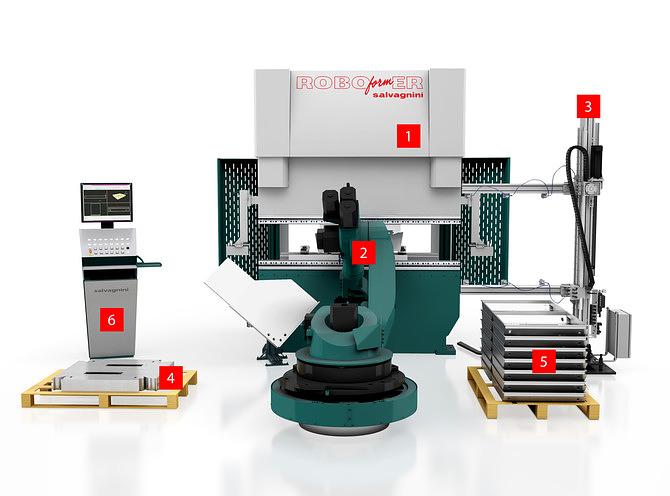

RoboFormer

From design to end-product for companies who base their competitive advantage on automation and flexibility. The cell’s components are:

Punching Centers

S1 Hybrid Punching Machine

The S1 hybrid punching machine satisfies the growing requirement for punching flexibility and productivity with its distinctive features such as the multi-press head and flexible automation.

S4 Punching/Shearing Machine

The S4 integrated punching/shearing offers an array of technology that guarantees high performance and process efficiency.

Automation

Please contact us for information on how to automate your facility.

More Info Video 1 Video 2 Video 3 Contact Us