Menu

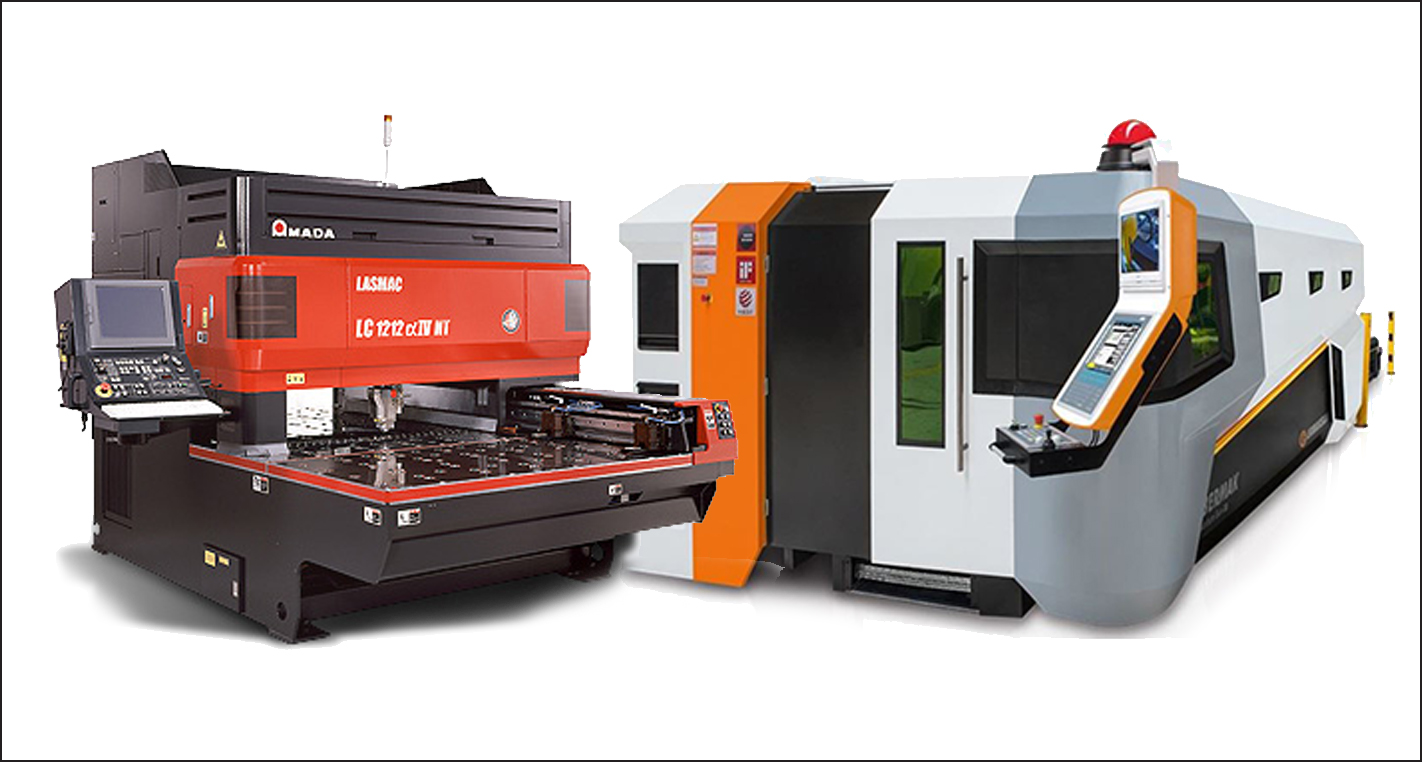

CO2 or Fiber? Which laser is “better”? The fiber laser technology has been around for over a decade now and has changed the new industry ‘norm’ from CO2 to fiber. As laser manufacturers around the globe have strayed away from producing CO2 lasers and have all been exclusively selling fibers, one would think that CO2 lasers are now obsolete and has no place in the market – this, however, could not further from the truth.

For a customer who is in the market for a laser, how do they determine which is a better fit for them? Most customers would most likely fall into one of these two categories:

- This is my first laser purchase and am new to the laser cutting industry.

- I already have a CO2 laser but am currently looking to upgrade.

In either scenario, the questions to ask myself would be:

- What type of material and how thick will I be looking to cut?

- How much work will be flowing through this machine?

CO2 LASERS – PROS AND CONS

CO2 Pros:

- Cost. You can get into a used CO2 machine at a fraction of the cost of a new Fiber.

- Finding a quality, used, CO2 machine will be far easier and much more economical.

- CO2 lasers for the most part will outperform cutting thicker material in anything ¼” and above.

CO2 Cons:

- Cost. When comparing a new CO2 to a new Fiber, the CO2 machines will consume far more power than the fiber.

- There are much more consumable parts in the CO2 compared to the fiber.

- Used CO2 lasers usually will need to have the turbo blower, vacuum pump and optics replaced every 12k – 24k hours or so which can cost anywhere from $12k - $25k.

FIBER LASERS – PROS AND CONS

Fiber Pros:

- Fiber lasers can cut thinner material up to 400% faster than a Co2 Laser.

- Reflective material? No Problem! You can cut Aluminum, copper, and Brass with ease.

- No need to worry about Consumables, Gases, Optics, and Mirrors because a Fiber Laser doesn’t require them. This translates into Low maintenance cost.

- Co2 average maintenance is every $12k-$24k hours and can run about $12k-$25k and in a Fiber it is close to 100,000 hours and at a fraction of the cost.

- The hourly usage for a Fiber Laser is about half of what you would expect from a Co2.

Fiber Cons:

- The cost of a New Laser is significantly higher than a CO2. The initial investment is a lot higher than a CO2 laser especially if you are looking into a used machine.

- Looking for a used option? The used Market will have a very slim selection if any.

- Beware of the first generation Fiber optics due to many issues arising.

In conclusion, determining which type of laser is the better fit will weigh heavily on what stage you are at in the laser cutting market. A start up company may be better off finding a 15 – 20 year old machine whereas the shop pumping a ton of work in and out of their facility may be better off going with a new fiber laser. The harder decision will be the shops who already have a CO2 laser and are looking to upgrade. Our recommendation would be that if you looking to go new, go with a fiber and not a CO2. The CO2 will probably be the better option only if you are looking to go used.

Let Manufacturing Solutions help you find the laser that is the right fit for your Company and its laser cutting needs. We offer a great selection of New and Quality Used Machinery. Give us call, we’re here to help.